|

Introduction: Introduction:

|

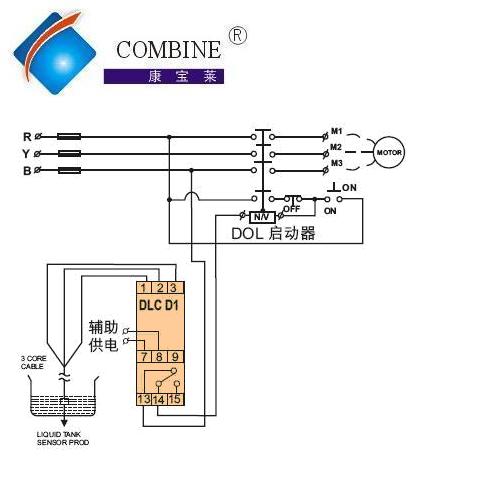

| It is a Diesel Level Controller. It is best suitable for monitoring single level overflow / dry run alarm in the Diesel Fuel tank. Multiple relays can be used with independent functions. Applications with Diesel Fuel tanks of Diesel powered Generators, Boilers, Screw compressors, Fire Fighting Pumps etc. For 2 levels 2 DLCD1 can be used. It is available for non-conductive liquids. It is supplied with Single Fork Type sensor FRKP 1 to sense the fuel level. This sensor is mounted either from TOP or SIDE wall on the fuel tank with its End Tip immersed in the fuel tank at the desired position. It is energizes when Sensor tip is inside the liquid & is de-energizes when level drops below sensor. | |

|

|

| Features: |

· Operates by sensing the continuity of Infra Red optical signal through the Transmitter & Receiver of the Fork Type Prod Sensor tip.

| |

|

| |

|

|

| Application Areas: |

| Oil Cooled machines Oil cooled Pumps Engine Control Panels Storage Tanks Oil water separator machines Compressors Oil fired Boilers Diesel Locomotive Machinery Filter press machines Spark Erosion machines Cooling Oil Pump control Pump protection, Low Fuel Level Alarm Day tank Fuel Level Monitor Oil spill Level Monitor Oil Leak Alarm Fuel Tank Level Monitor Diesel Fuel storage level Coolant liquid level monitor Filter Oil Level Kerosene Tank Level Monitor | |

|

|

| Technical Specifications: |

|

|

|

|

|

Specifications |

| 1 |

Auxiliary Supply |

110 / 230 / 415 V AC /12 V / 24 V DC |

| 2 |

Output Contacts |

1 CO |

| 3 |

Input Sensors |

1 (FRK P1) |

| 4 |

Sensitivity |

N. A. |

| 5 |

Trip Time Delay |

Less than 5 sec |

| 6 |

Weight |

Unit 300 gms.; Sensor (each) 100 gms. |

| 7 |

Dimensions (mm) |

Unit Overall (L x W x D) 76 x 30.5 x 117.5; Mounting (L x W) 68 centre to centre |

| 8 |

Sensor |

Overall 18 (Dia) x 75 (L) | |